Get Up to 40% OFF New-Tires Styles

AutoParts * Limited time only.Call us now847-200-0974

Controls Fuel Injector Module Wiring Harness

Fuel injector controls refer to the electronic systems and components responsible for managing the operation of fuel injectors within an engine. In an internal combustion engine, fuel must be mixed with air in exact proportions and injected into the combustion chamber at precise moments to achieve optimal performance. Modern fuel injector controls accomplish this by using data from various sensors—such as oxygen sensors, mass airflow sensors, and throttle position sensors—to determine the ideal fuel-air mixture and injection timing. The Engine Control Unit (ECU) processes this data and sends commands to the fuel injectors, ensuring that the right amount of fuel is delivered at the right moment.

How Do Fuel Injector Controls Work?

The process begins with the collection of real-time data by a network of sensors strategically placed throughout the engine. These sensors monitor numerous parameters, including:

- Engine Speed: How fast the engine is running.

- Airflow: The amount of air entering the engine.

- Throttle Position: The degree to which the throttle is open.

- Temperature: Both ambient and engine temperatures.

- Oxygen Levels: The oxygen content in the exhaust, which indicates how efficiently the fuel is being burned.

This information is transmitted to the ECU, which utilizes advanced algorithms to calculate the precise timing and duration of fuel injections. The fuel injector control system then sends electronic signals to the fuel injectors, causing them to open and close with exact precision. This results in the correct amount of fuel being sprayed into the combustion chamber at the optimal moment, ensuring complete and efficient combustion.

Key Features and Benefits

Precision and Accuracy

Fuel injector controls enable engines to deliver fuel with high precision. By constantly adjusting the fuel injection parameters based on real-time sensor data, the system ensures that the engine always receives the ideal air-fuel mixture. This precision is critical for maximizing power output and fuel efficiency while minimizing wasted fuel.

Enhanced Engine Performance

When fuel is injected with exact timing and quantity, the engine operates more smoothly and efficiently. This leads to improved throttle response, better acceleration, and overall enhanced engine performance. In high-performance vehicles, the benefits of precise fuel injector control are particularly noticeable.

Improved Fuel Economy

Efficient fuel management is key to reducing fuel consumption. By ensuring that fuel is used only when necessary and in the right amounts, fuel injector controls contribute significantly to better fuel economy. This not only reduces operating costs for drivers but also lowers the environmental impact of the vehicle.

Emission Reduction

Incomplete combustion is a major source of harmful emissions. Fuel injector controls help ensure that fuel burns completely and efficiently, reducing the emission of pollutants such as unburned hydrocarbons and nitrogen oxides. This is increasingly important as global emission standards become more stringent.

Adaptive Technology and Diagnostics

Modern fuel injector control systems are designed to adapt to various driving conditions. They can adjust fuel injection parameters in real time based on engine load, acceleration, and other factors. Additionally, many systems include diagnostic features that can detect potential issues before they become serious problems, enabling preventive maintenance and reducing the risk of engine damage.

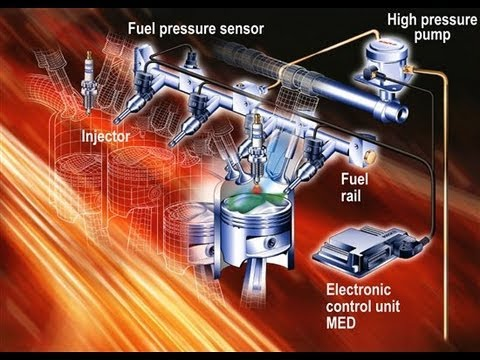

Components of a Fuel Injector Control System

A comprehensive fuel injector control system includes several interrelated components:

- Engine Control Unit (ECU): The central processor that interprets sensor data and calculates the optimal fuel injection parameters.

- Fuel Injectors: The devices that physically spray fuel into the engine's combustion chambers.

- Sensors: Instruments that monitor various engine parameters, such as air temperature, engine speed, and oxygen levels.

- Control Modules: Specialized units that manage the precise timing and duration of fuel injections.

- Wiring and Connectors: These ensure reliable communication between the ECU, sensors, and fuel injectors.

The Evolution of Fuel Injector Controls

Fuel injector controls have evolved tremendously over the past few decades. Early fuel injection systems were primarily mechanical and lacked the precision of modern electronic systems. Today, advanced digital systems use real-time data and sophisticated algorithms to control fuel injection with unprecedented accuracy. This evolution has led to significant improvements in engine performance, fuel efficiency, and emission control.

As technology continues to advance, the next generation of fuel injector controls is expected to incorporate artificial intelligence and machine learning. These innovations will enable systems to learn from driving patterns and further refine fuel delivery, pushing the boundaries of engine efficiency even further.

Importance in Modern Automotive Engineering

Fuel injector controls are integral to the overall performance of an engine. They contribute to:

- Optimized Combustion: By ensuring the perfect air-fuel ratio, these controls maximize the efficiency of the combustion process.

- Enhanced Power Output: Precise fuel delivery means the engine can produce more power when needed, improving acceleration and overall performance.

- Reduced Maintenance Costs: Efficient combustion reduces the buildup of residues and wear on engine components, potentially extending the engine's lifespan.

- Environmental Benefits: Improved fuel efficiency and complete combustion contribute to lower emissions, supporting a cleaner environment.

Future Trends and Innovations

The future of fuel injector controls looks promising, with ongoing advancements poised to further improve engine efficiency and performance. Future trends may include:

- Integration with AI and Machine Learning: These technologies could allow systems to adapt more dynamically to varying driving conditions, providing even more precise fuel control.

- Enhanced Sensor Technology: As sensor technology advances, fuel injector controls will have access to even more accurate data, enabling finer adjustments in fuel delivery.

- Greater Emphasis on Sustainability: With growing concerns about environmental impact, future systems will likely focus even more on reducing emissions and improving fuel economy.

Conclusion

Fuel injector controls are the unsung heroes of modern engine management systems. They ensure that every drop of fuel is used efficiently, enhancing engine performance, improving fuel economy, and reducing emissions. As automotive technology continues to evolve, these systems will remain at the forefront of innovation, playing a vital role in the development of smarter, more efficient engines.

Understanding the role of fuel injector controls offers valuable insights into how modern vehicles achieve optimal performance. For automotive engineers, mechanics, and enthusiasts alike, these systems are a testament to the incredible advancements in technology that drive today's automotive industry. With their continued evolution, fuel injector controls will help shape the future of engine efficiency, paving the way for cleaner, more powerful, and more reliable transportation.

Fuel injector controls are more than just a technical component—they are a cornerstone of modern automotive engineering, ensuring that our engines run as efficiently and effectively as possible. Whether you're maintaining your vehicle or working on the next breakthrough in engine technology, understanding these systems is essential to appreciating the complex interplay between fuel, air, and power that drives our world.

.webp)